When we look back to the technological revolutions of the 20th century, most of the life changing technologies were very concretely physical: Electrical power generation and grids, trains and railways, antibiotics and vaccines, automobiles and airplanes, etc. As the century progressed and turned, however, the card-carrying innovations turned distinctly more virtual. While the telegraph, telephone, radio and television were early examples of such virtual technology, the real trend break came with the advent of the computer, and accelerated in turn with the personal computer, the Internet and the world-wide web, the smartphone and social media.

This dominance of the virtual can be vividly illustrated by considering the nature of the celebrated FAANG companies (Facebook, Apple, Amazon, Netflix and Google). Among these, only Apple is primarily known for their innovation in physical technologies, and even in that case the physical objects in question are hardware vehicles for their software. As Peter Thiel famously quipped: “We wanted flying cars, instead we got 140 characters”.

Thiel and others have put a lot of thought into what may have caused this redirection of innovation efforts. Some of the most commonly suggested explanations include:

- The low-hanging fruit may have been already picked.

- The regulatory environment became much more onerous and hostile to innovation as the 20th century progressed.

- Digital products simply make for better business cases, since much less capital investment is needed to get a digital product out on the market, and the marginal cost of production goes to zero as the number of copies increases.

- A turn to short-termism and incrementalism in both science and technology, as standardized metrics have overtaken gut instincts and personal risk appetites in capital allocation.

- The relative peace and stability, and consequent lack of arms races may have removed incentives for moon-shots (literal and metaphorical).

Whatever the reasons, there is a very great likelihood that if you were to enumerate ten physical items that have drastically changed the life of yourself or your family in the 20th century, most of them would have already been widely distributed in developed countries by about 1960, or if not, the value that comes from them is primarily computational in nature.

Looking over the horizon, however, I see a clear macrotrend of technology returning to the physical realm. This time, however, it is not driven by state-of-the art wind tunnels, marginal improvements in chemical processes or internal combustion engines, but something else entirely. This time, it is digital technology that has broken out of its virtual bonds to enter and colonize the physical world. There is a broad confluence of trends along these lines:

- additive manufacturing (i.e. 3D printing),

- Internet of things,

- self-driving cars,

- robotics,

- personalized medicine,

- gene sequencing and editing,

- smart electrical grids,

- digital twins,

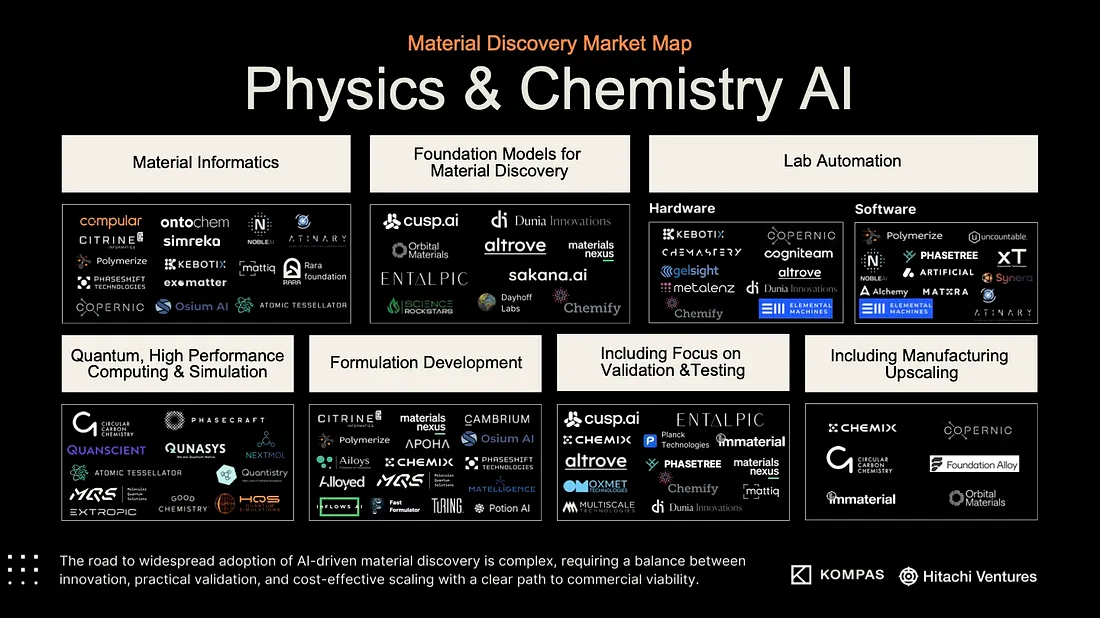

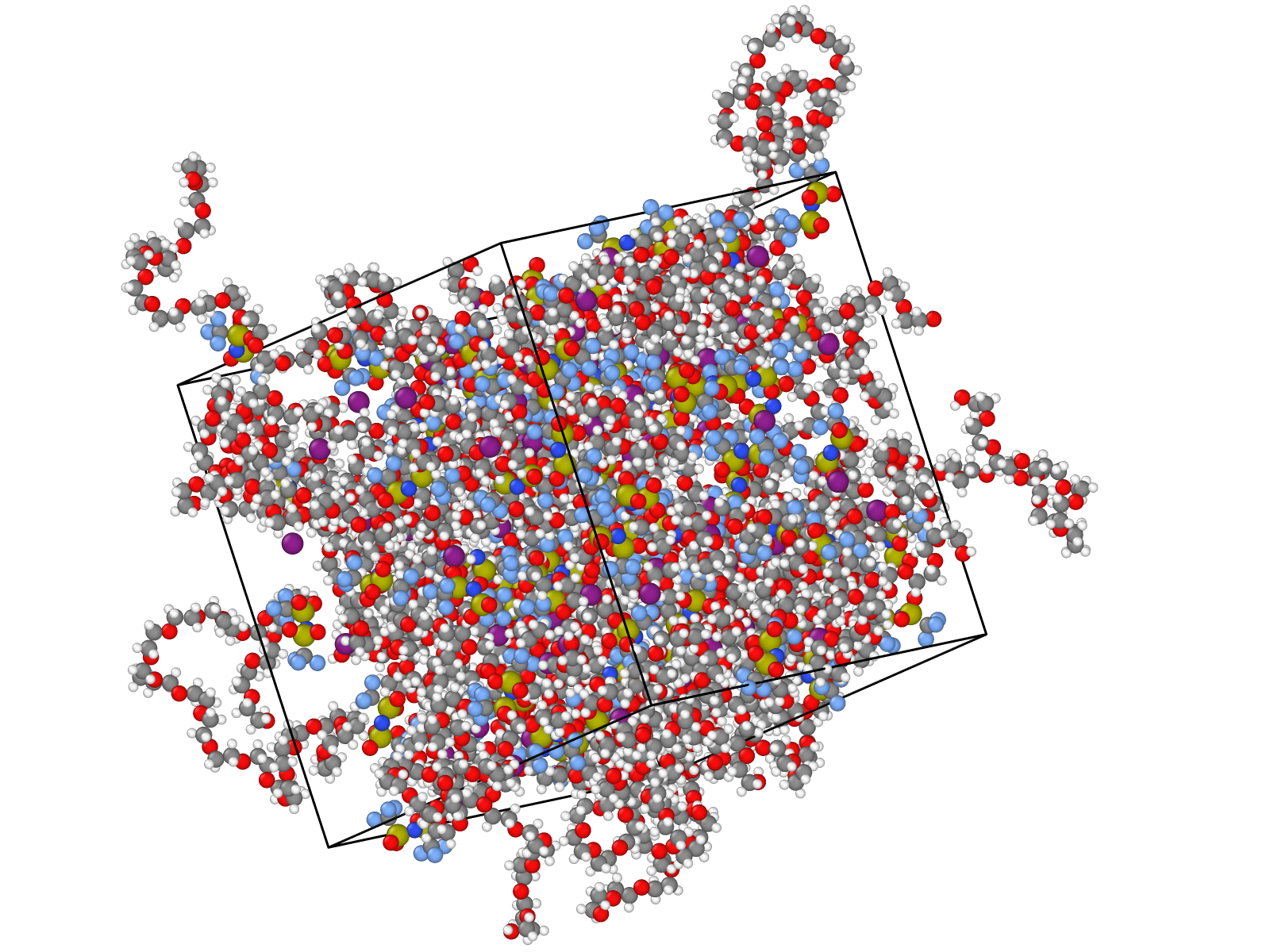

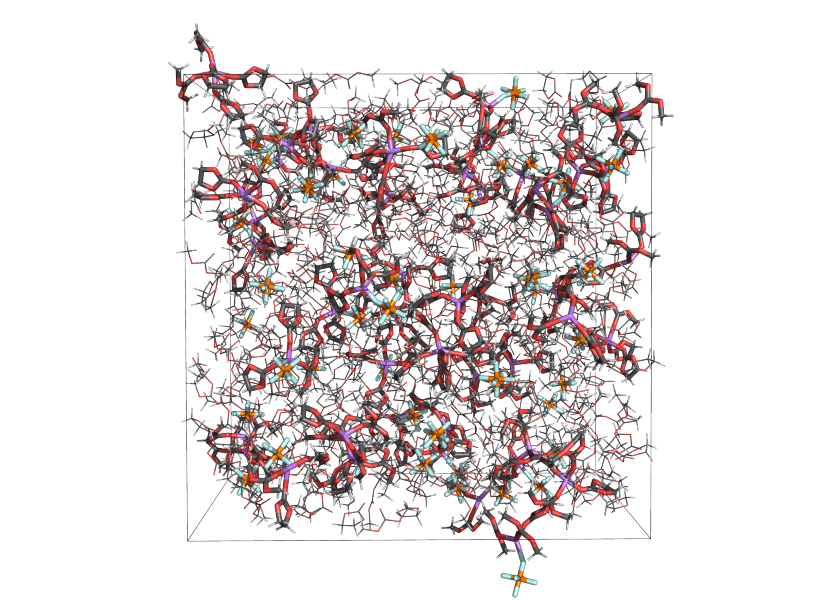

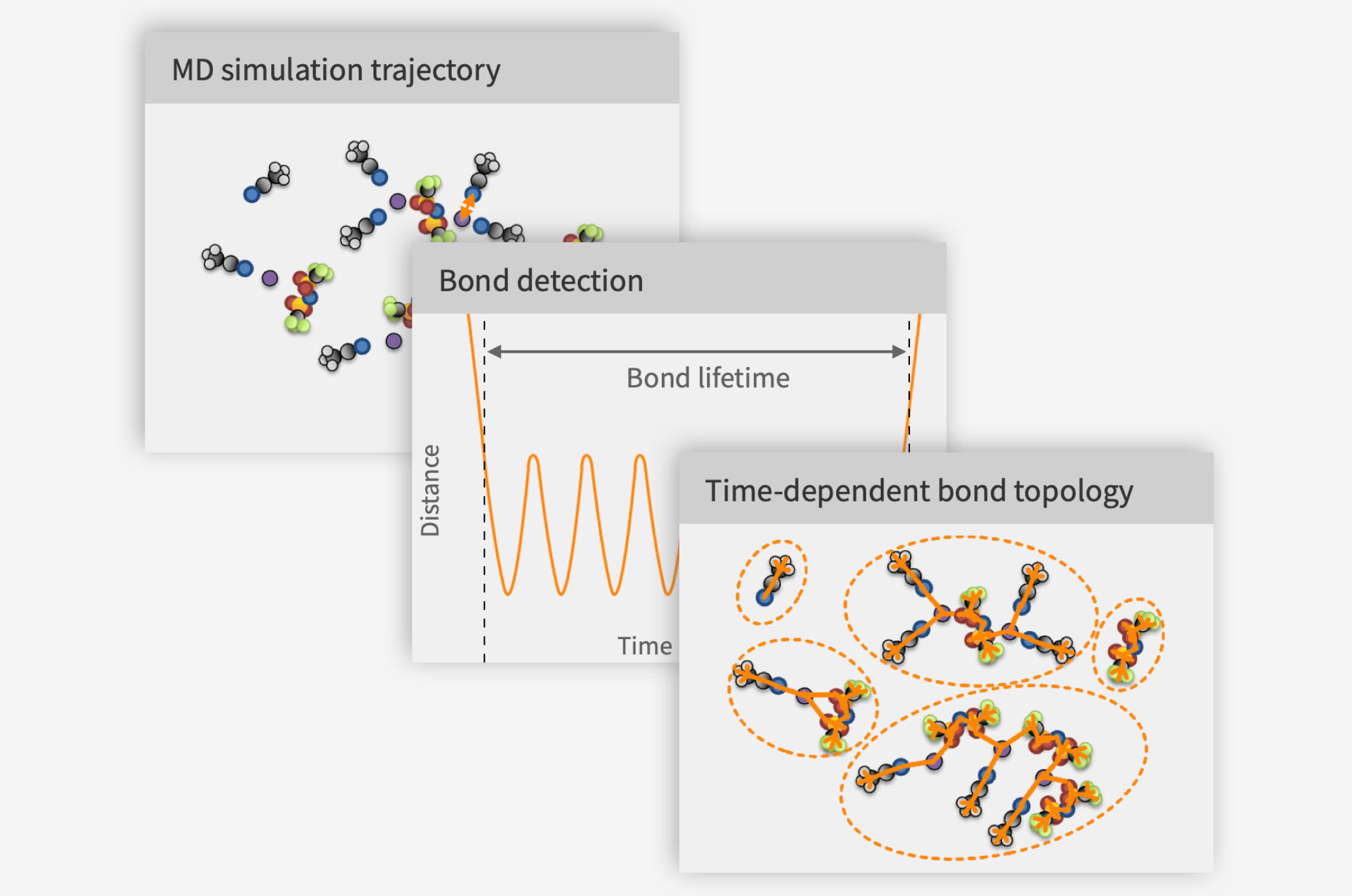

- digital materials and molecule discovery,

- computer-aided design of experiments,

A few different reasons can be identified for why this all happens now. One part of it is that our processing power and software capabilities have become mature enough for these technologies to make economic sense. The other side of the coin is that these capabilities have strengthened the economic case for sensors and other peripheral hardware, which have also become mature enough to spread throughout the economy.

The economic drivers for these transitions have commonalities with what drove the turn to digital technology in the first place: lowered capital requirements even for physical product companies as the part of the company that directly deals with physical processes gives way to an increasing digital fraction of operations. In addition, operating costs are lowered by replacing labor with automation and reducing redundancy and routine check-ups as states-of-health can be tracked in real time. Last, but not least, these technologies push the boundaries of what is possible in terms of reliability, productivity, health and quality of products.

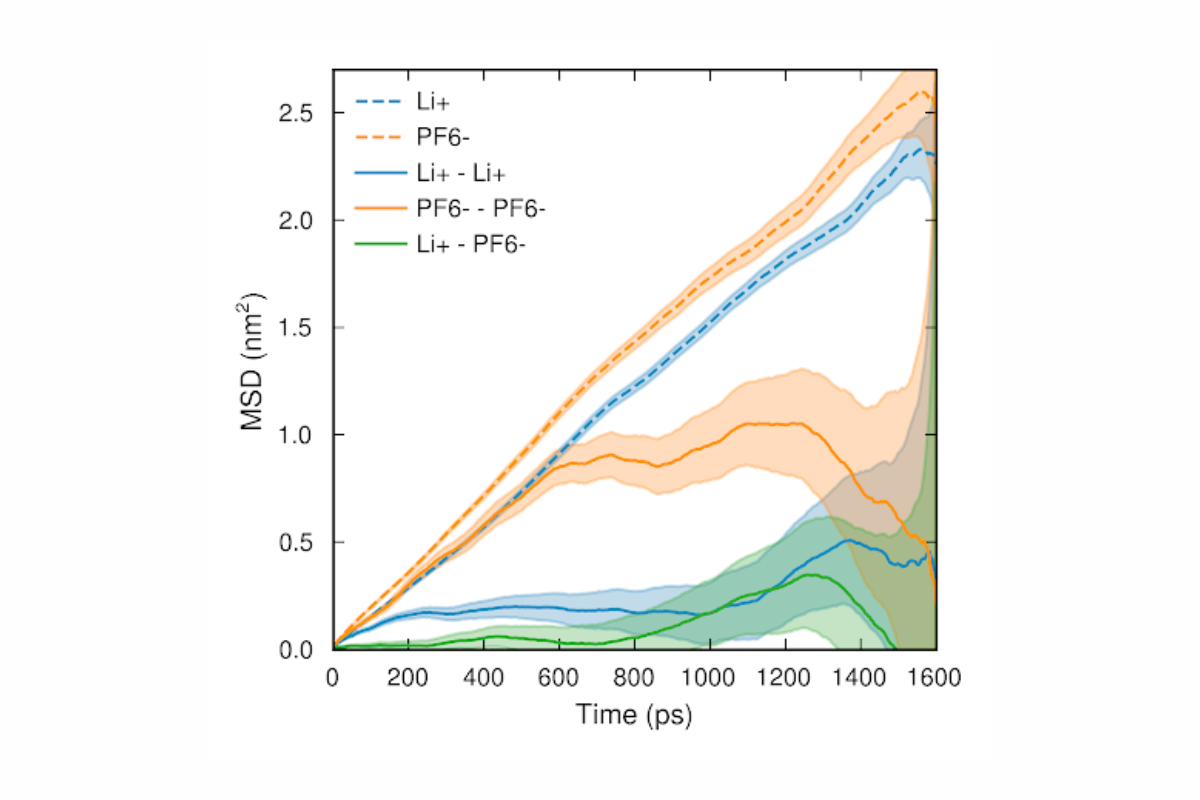

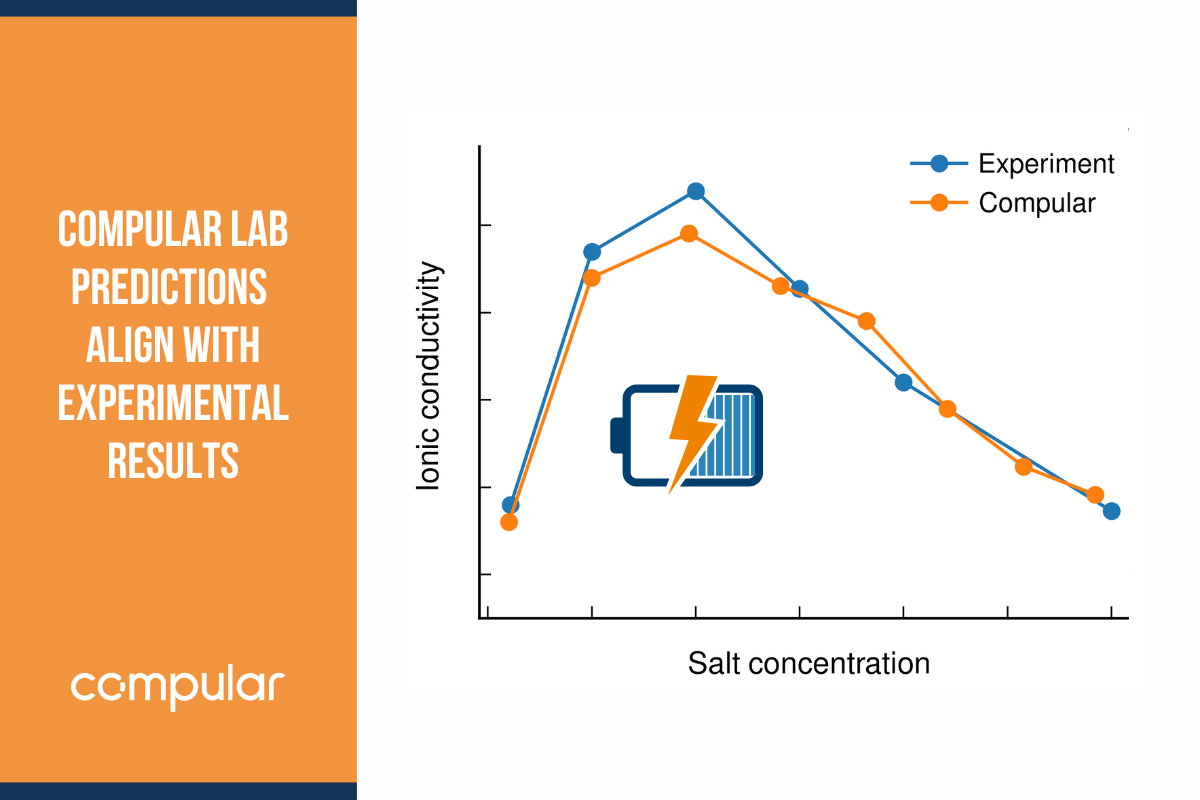

At Compular we are also part of ushering in this transition by digitalizing materials development by simulations, informatics, and design of experiments, with a near-term focus on liquid battery electrolytes. If you would like to learn more, go to compulartech.com or send an email to .

Rasmus Andersson, PhD

CTO Compular