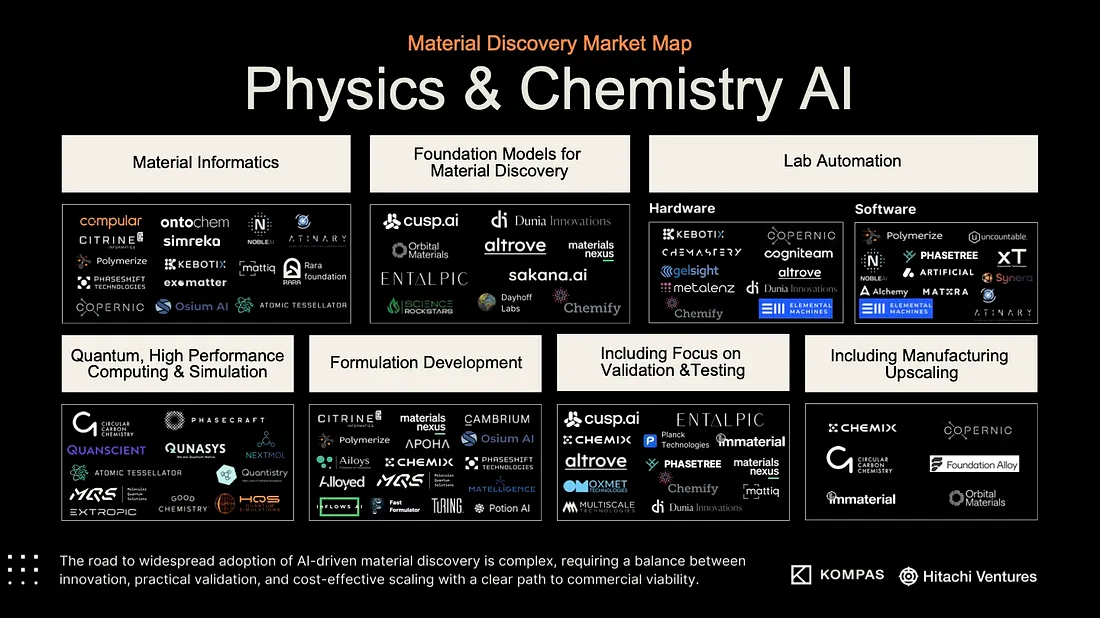

Digitalization is revolutionizing materials R&D, yet many companies are unsure how to harness its power to enhance their products. Molecular dynamics offers invaluable insights into properties that influence the performance of materials and products. But what if your company lacks in-house expertise? Can you still reap the benefits?

Traditionally, R&D managers and computational scientists might have said no. Powerful simulation packages have been developed by and for computational experts, mainly due to their academic origins. Academic researchers prioritize flexibility and power in their tools, while spending countless hours mastering them and communicating with the creators whenever things are unclear. However, industrial R&D teams, focused on product development, cannot afford such luxuries.

Although many of these tools are open source for academic use, commercial companies often market them to industrial clients with dual licenses. These commercial versions often include improved user experiences, allowing different modules to be combined and data to be transferred between them. Cloud-based simulation and analysis, as well as data sharing among users, are also common. However, these tools still cater to computational experts, excluding experimentalist chemists and materials scientists who could have otherwise benefited from them.

This predicament is not inevitable. Simulations can be automated to a high-quality standard, comparable to that achievable by a computational scientist. If this seems too good to be true, allow me to clarify. It is currently not possible to automate high quality simulations across all material space using the same modeling choices and parameters.

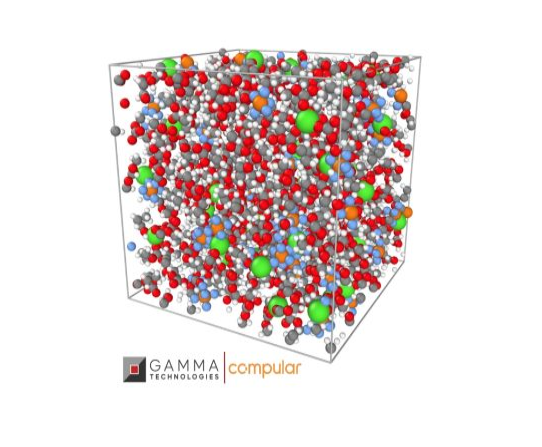

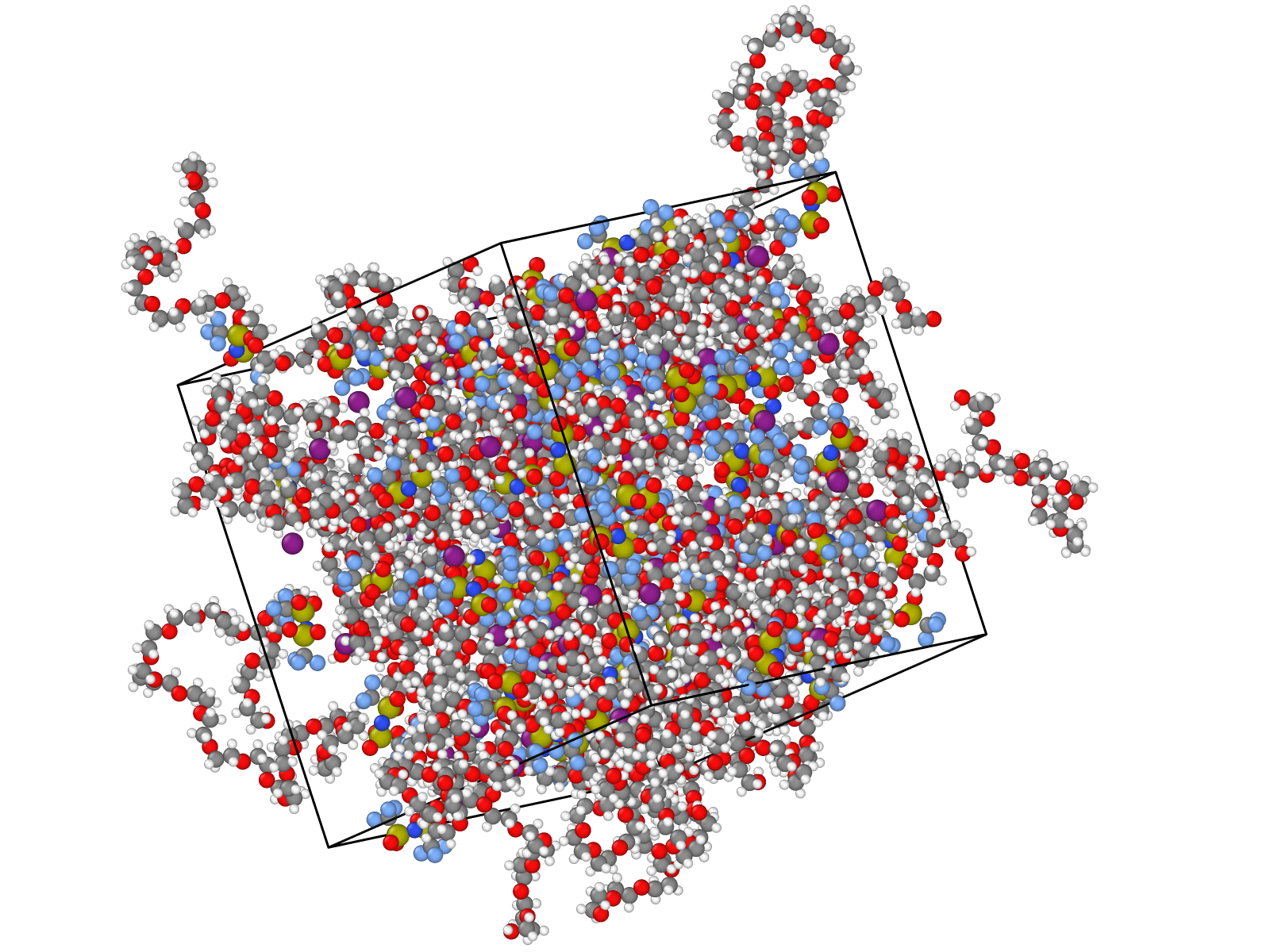

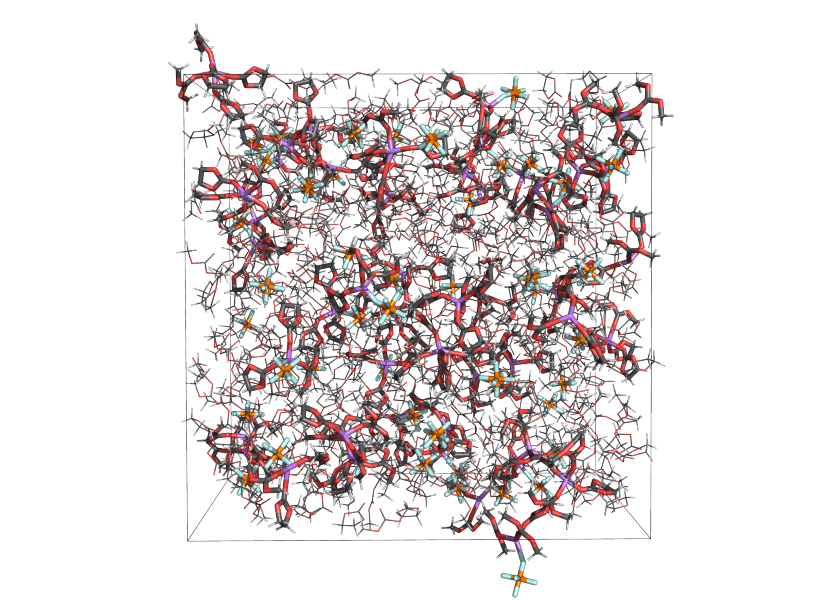

However, it is possible to do so for a limited range of materials, say liquid electrolytes for lithium-ion batteries.

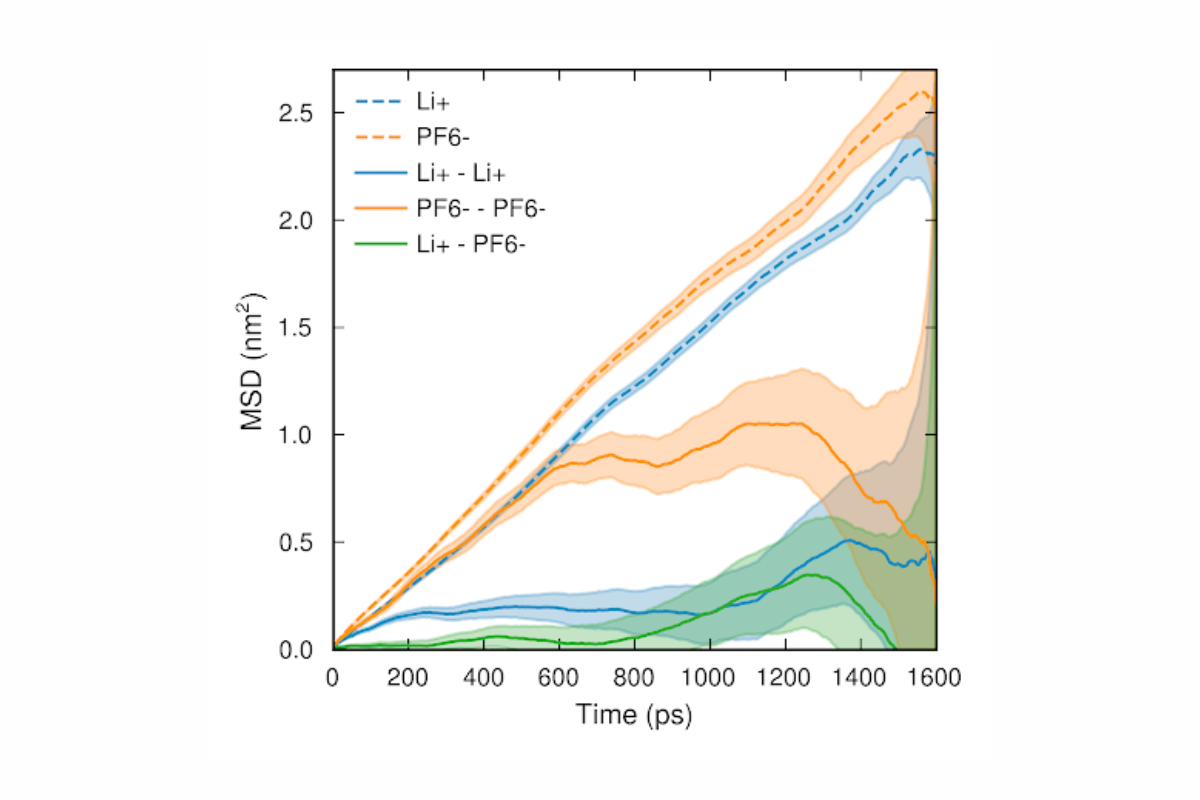

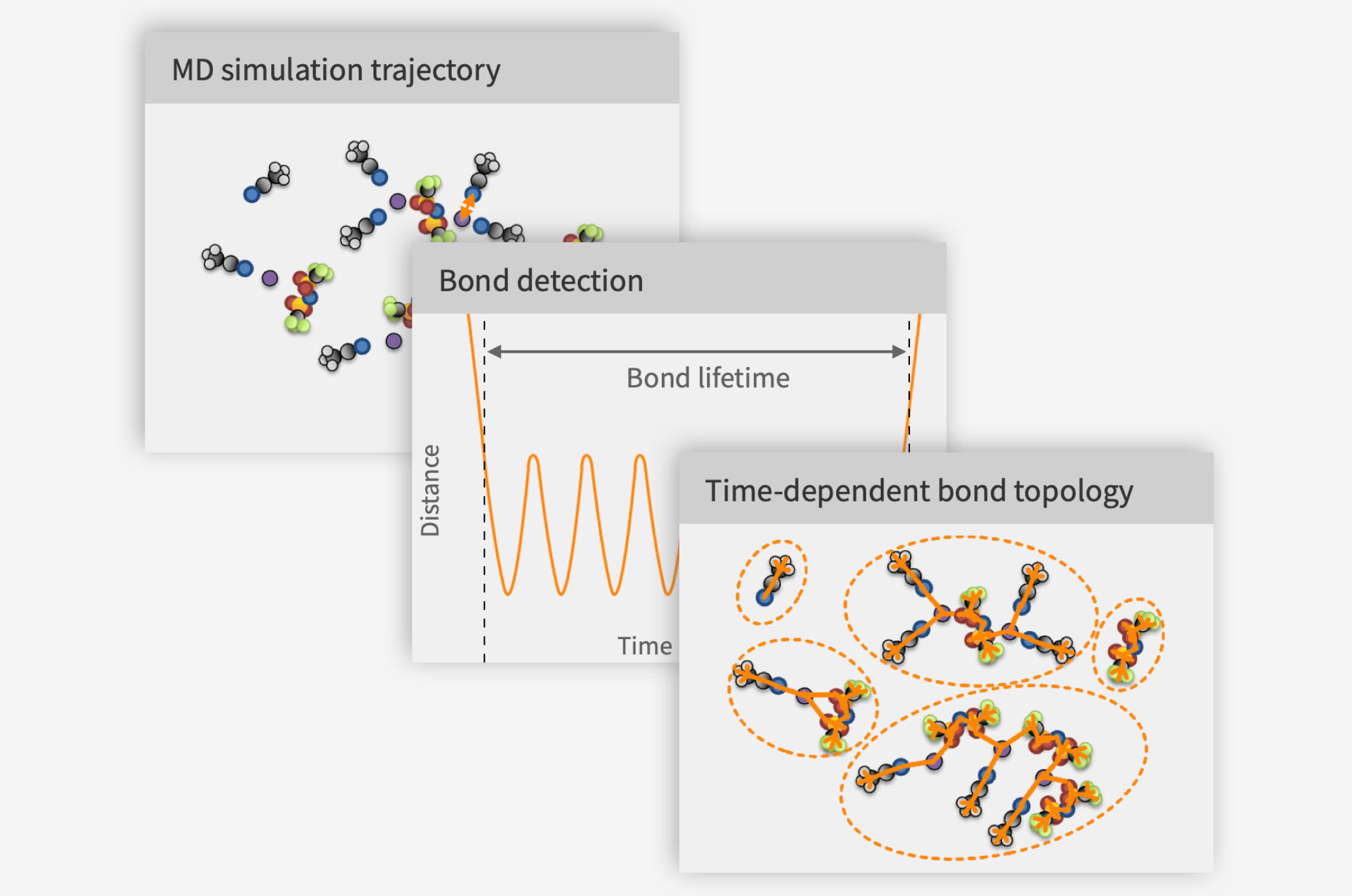

In reality, computational scientists often run related simulations in batches, covering a narrow chemical space. Rigorous researchers also seek experimental validation to ensure their workflow and modeling choices are accurate enough for their goals. However, this process is repeated by every computational researcher and mostly redone with every new project.

A more efficient approach would involve incorporating these learnings into software, making them accessible to users exploring a similar materials space.

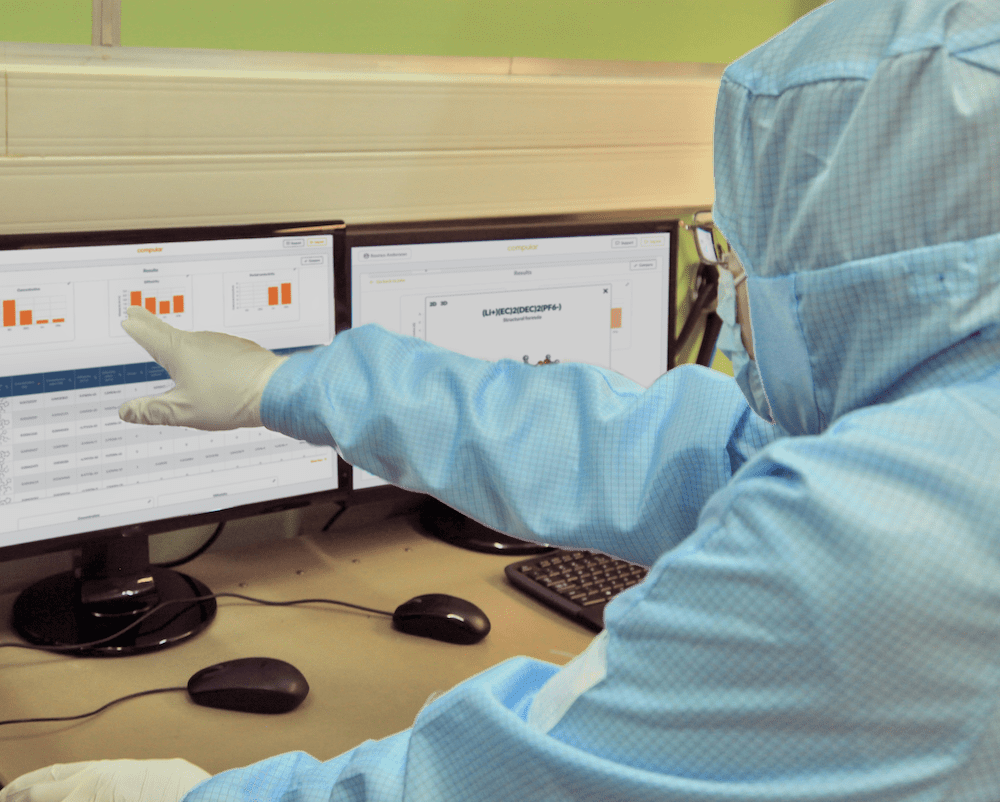

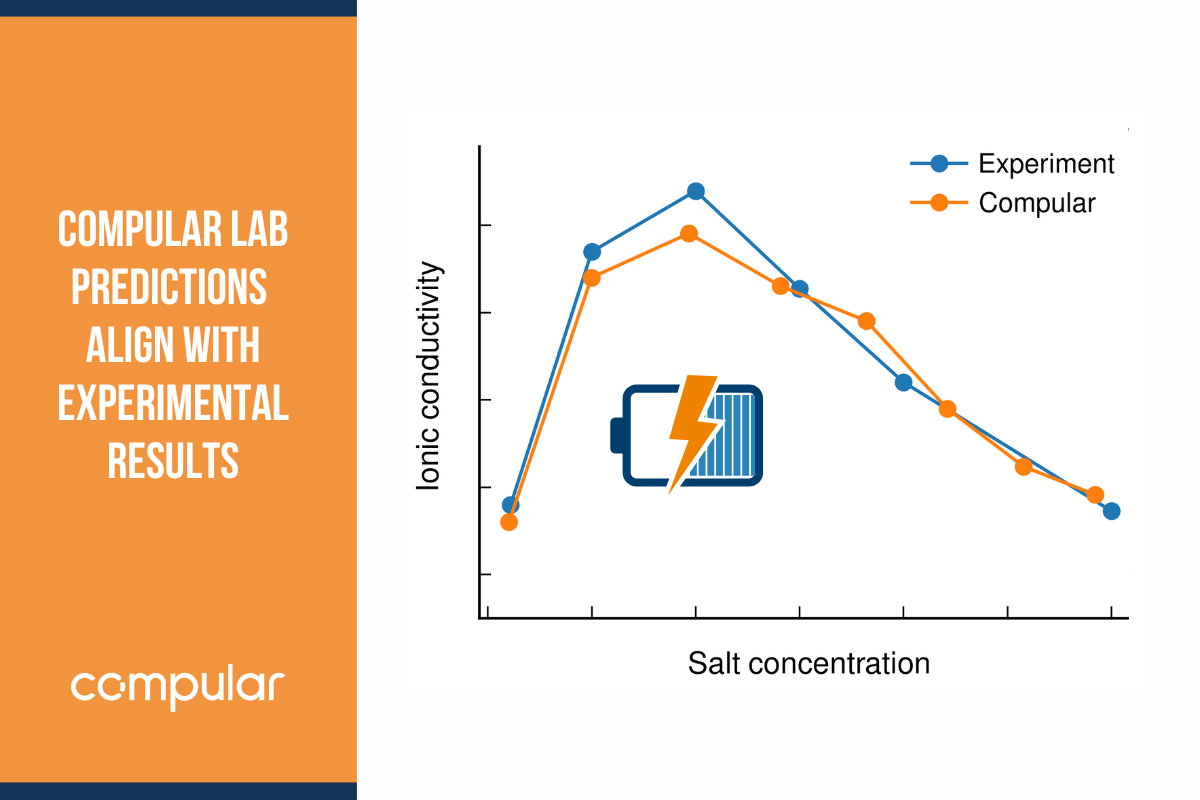

At Compular, we offer this solution, starting with liquid electrolytes for battery applications. As battery electrolyte simulation experts, we understand your research needs. To build trust, we begin every customer journey by validating our simulations against available data points (e.g., total conductivity, density, viscosity) to ensure accurate representation. With each new customer, we refine our processes and make necessary adjustments to our automated workflows.

With Compular, you can simply specify the compositions, temperature, and pressure you want to simulate. We automate the rest, from generating starting geometries, running simulations on optimal cloud-based hardware, analyzing results, and presenting them in a format that informs your decision-making.

Our services enable you to eliminate numerous candidate formulations without labor-intensive lab work, saving time and resources. Molecular dynamics simulations also provide insights that are difficult to obtain in the lab, such as cation conductivity, the impact of local structure on electrochemical stability, and the rate of solvation dynamics.

Moreover, we can assist you in selecting the next batch of systems to simulate, integrating our computational approach with your lab measurements. Stay tuned for more information on how we can support your materials R&D journey.

Rasmus Andersson, PhD

CTO Compular