Written by Somayeh Toghyani (GT), Peter Stopp (GT) and Magnus Rahm (Compular)

May 21, 2025

Beyond Experimentation: Predicting Battery Performance with Multi-Scale Models

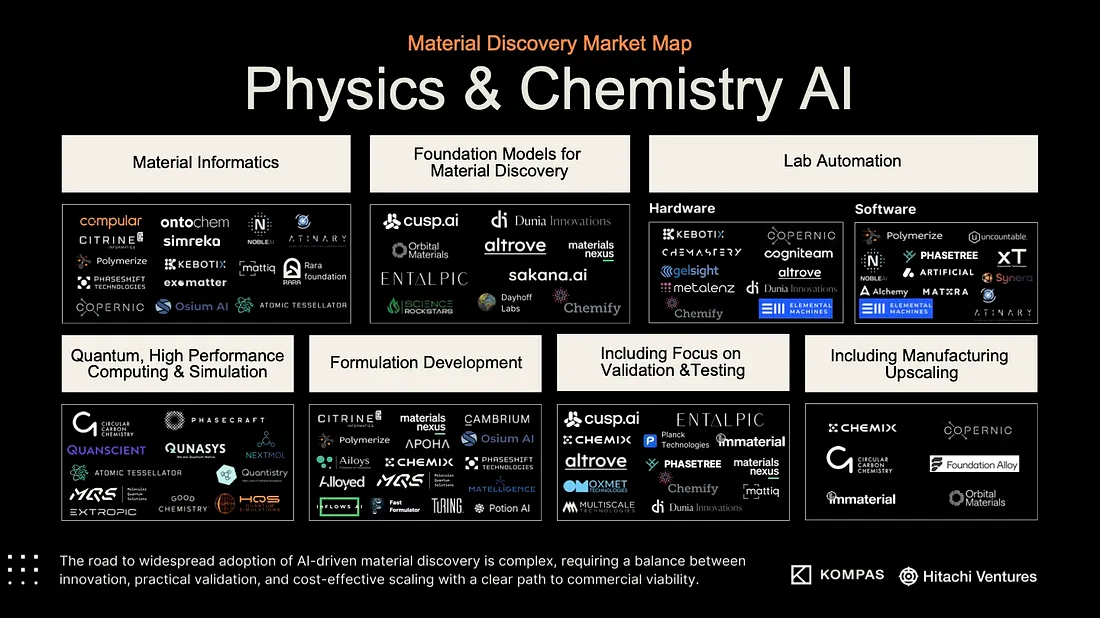

In today’s electrified world, designing better batteries goes far beyond trial-and-error testing. Engineers and researchers are increasingly turning to simulation to accelerate innovation and reduce development costs. Lithium-ion batteries power modern energy storage systems, from electric vehicles to grid storage. As demand grows for higher performance, longer lifespan, and improved safety, accurate battery modeling becomes increasingly important. A promising path forward involves uniting atomic-scale simulations with continuum models (multi-scale modeling) to enhance the fidelity of performance predictions.

Enhancing Battery Design Through Atomic and Continuum Model Integration

Multi-scale modeling approach accelerates the design of new battery materials, reducing reliance on time-consuming and expensive experimental testing. It enables:

- Faster material development: Atomic-scale simulations allow rapid exploration of new electrolytes and additives.

- Better battery optimization: Engineers can fine-tune battery performance for specific applications, such as high-power EV batteries or high-energy grid storage solutions.

- Improved safety and longevity: Accurate predictions help optimize electrolyte formulations, reducing risks associated with lithium plating and thermal runaway.

The Role of the Electrolyte in Battery Simulation

Achieving high predictability in battery modeling requires a deep understanding of each cell component, particularly the electrolyte, which is essential for lithium-ion transport between the electrodes. The electrolyte significantly impacts overall battery performance by influencing internal resistance, voltage behavior, and degradation over time. However, key electrolyte properties, such as ionic conductivity, lithium transference number, and diffusivity, are difficult to measure and highly sensitive to variables like temperature, concentration, and interactions with electrode materials.

Understanding Atomic-Scale Simulations in Battery Modeling

Continuum models—mathematical approaches that simulate battery behavior at the cell or system level by treating materials as continuous substances—such as the pseudo-two-dimensional (P2D) model, rely heavily on these properties to simulate ion transport and electrochemical behavior. Inaccurate values may lead to significant errors in predicting concentration gradients, voltage losses, and overall battery performance. Atomic-scale simulations—methods that simulate battery behavior at the molecular (or atomic) level by modeling individual particles or molecules—help estimate electrolyte properties across a wide range of conditions, improving the accuracy of continuum models and reducing reliance on experimental measurements.

Combining Atomic-Scale and Continuum Models for Better Insight into Battery Performance

To generate accurate electrolyte property data across various conditions, Compular has collaborated with Gamma Technologies. By integrating Compular’s molecular dynamics (MD) simulations with Gamma Technologies’ (GT) GT-AutoLion continuum model, it is possible to directly calculate fundamental electrolyte properties from atomic-level simulations.

To integrate Compular’s simulation with GT-AutoLion, an electrolyte with an additive (LiPF6 in EC:PC:EMC, 1:3:8 by volume, with 2% FEC) is simulated across varying salt concentrations and temperatures to study the performance of both high energy and high power-dense cells.

GT-AutoLion utilizes a physics-based P2D model to simulate battery charging and discharging. It divides the battery into three main regions—anode, cathode, and separator—discretizing them to capture critical electrochemical interactions (Figure 1). However, to ensure the accuracy of these models, precise electrolyte data is necessary. This is where MD simulations come into play.

Figure 1: Schematic view of the P2D model used in the GT-AutoLion tool

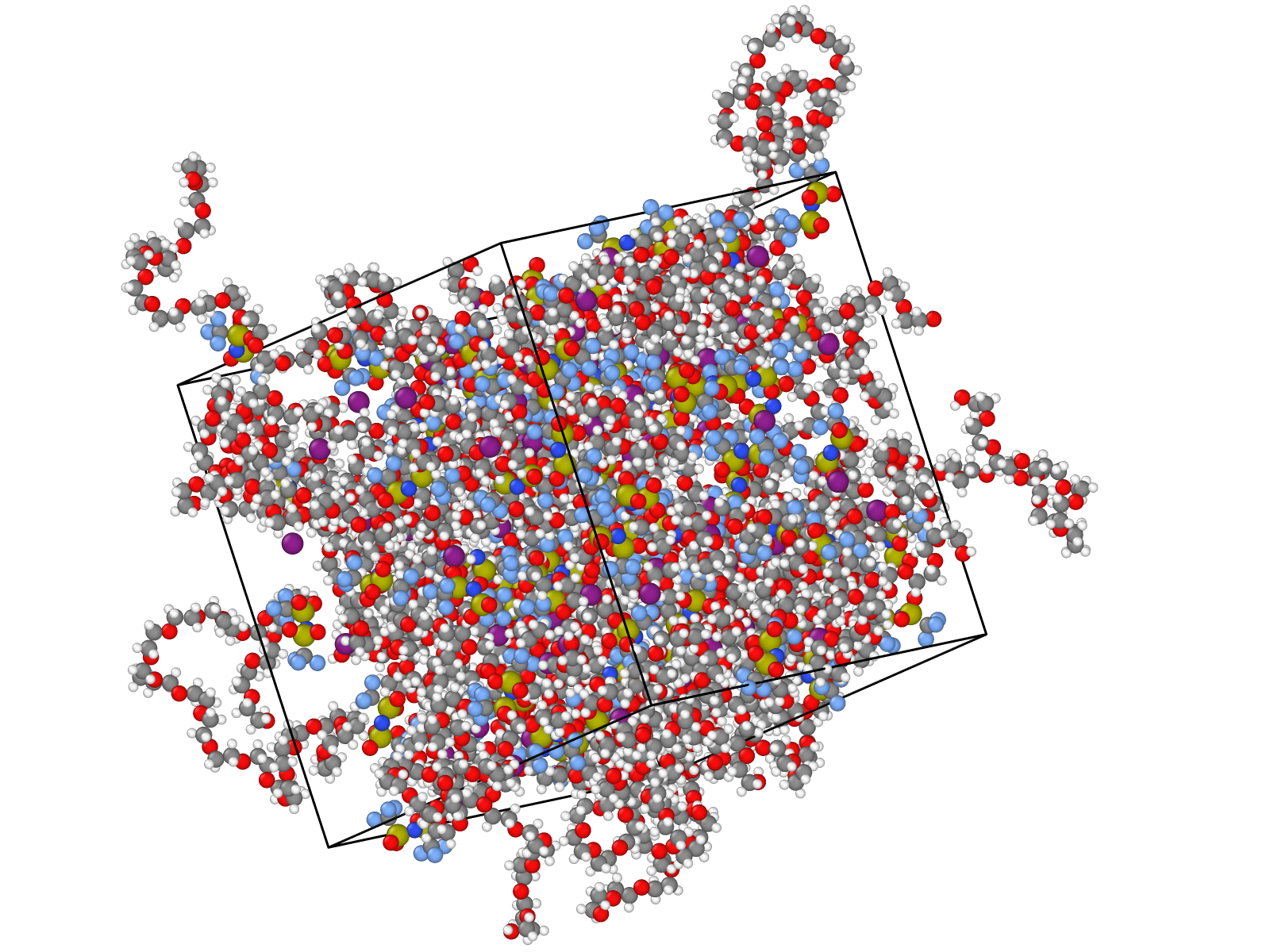

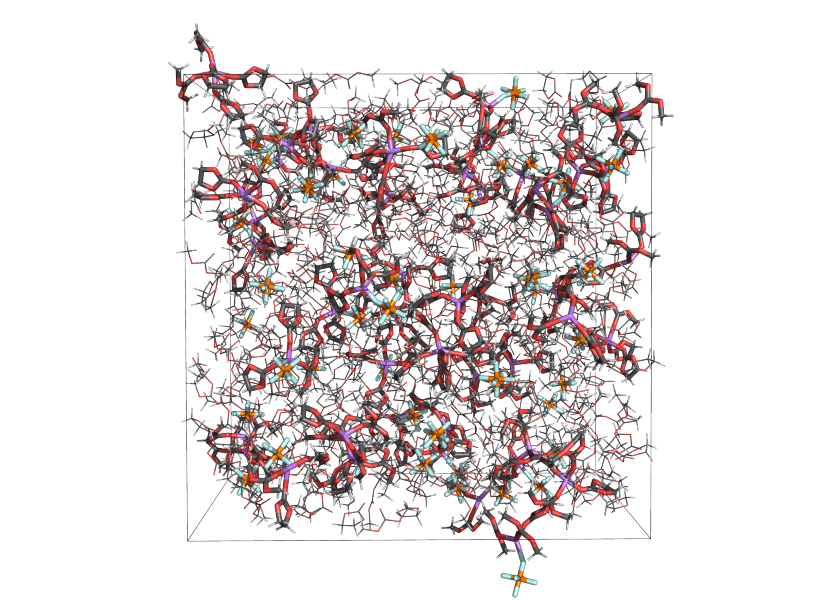

Compular Lab models electrolytes at the molecular level using MD simulations, simulating systems with about 5000 atoms. These atoms move according to the laws of physics, and we track their motion over time to observe how they interact. The simulations run at specific temperatures and salt concentrations, and for each condition, we record around 15 nanoseconds of ion movement.

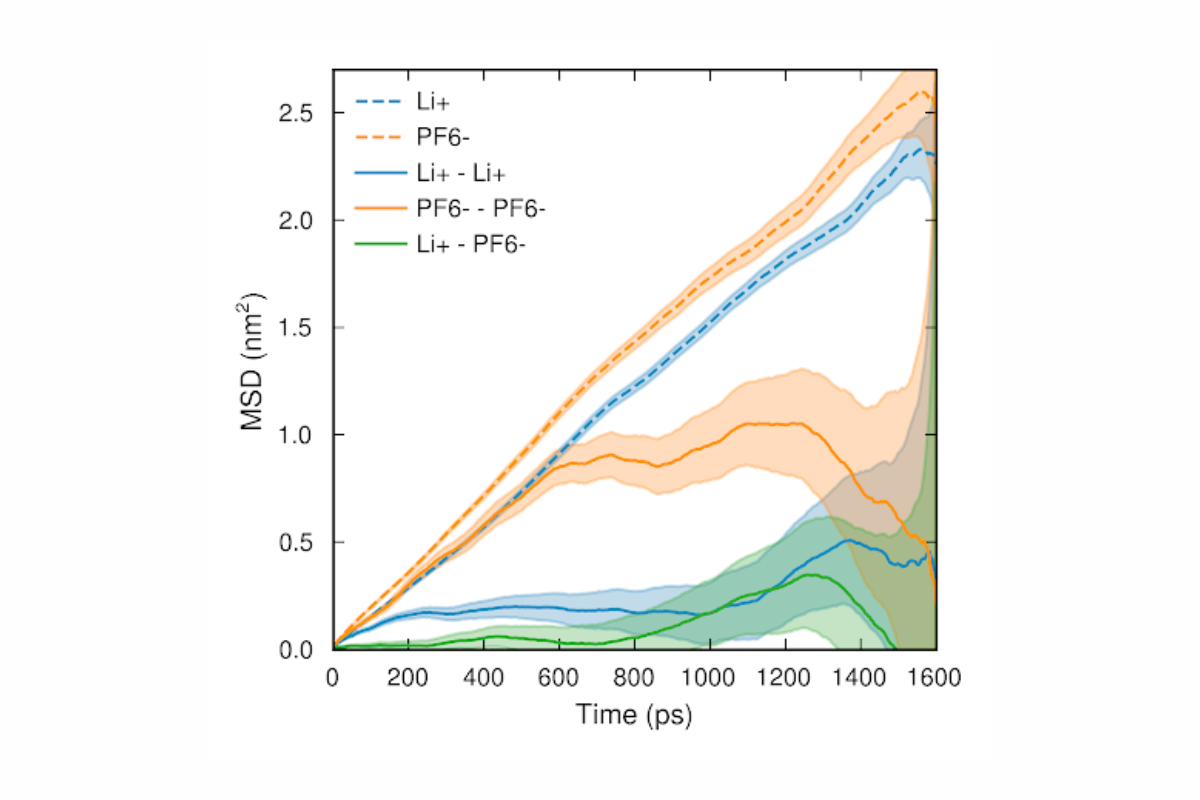

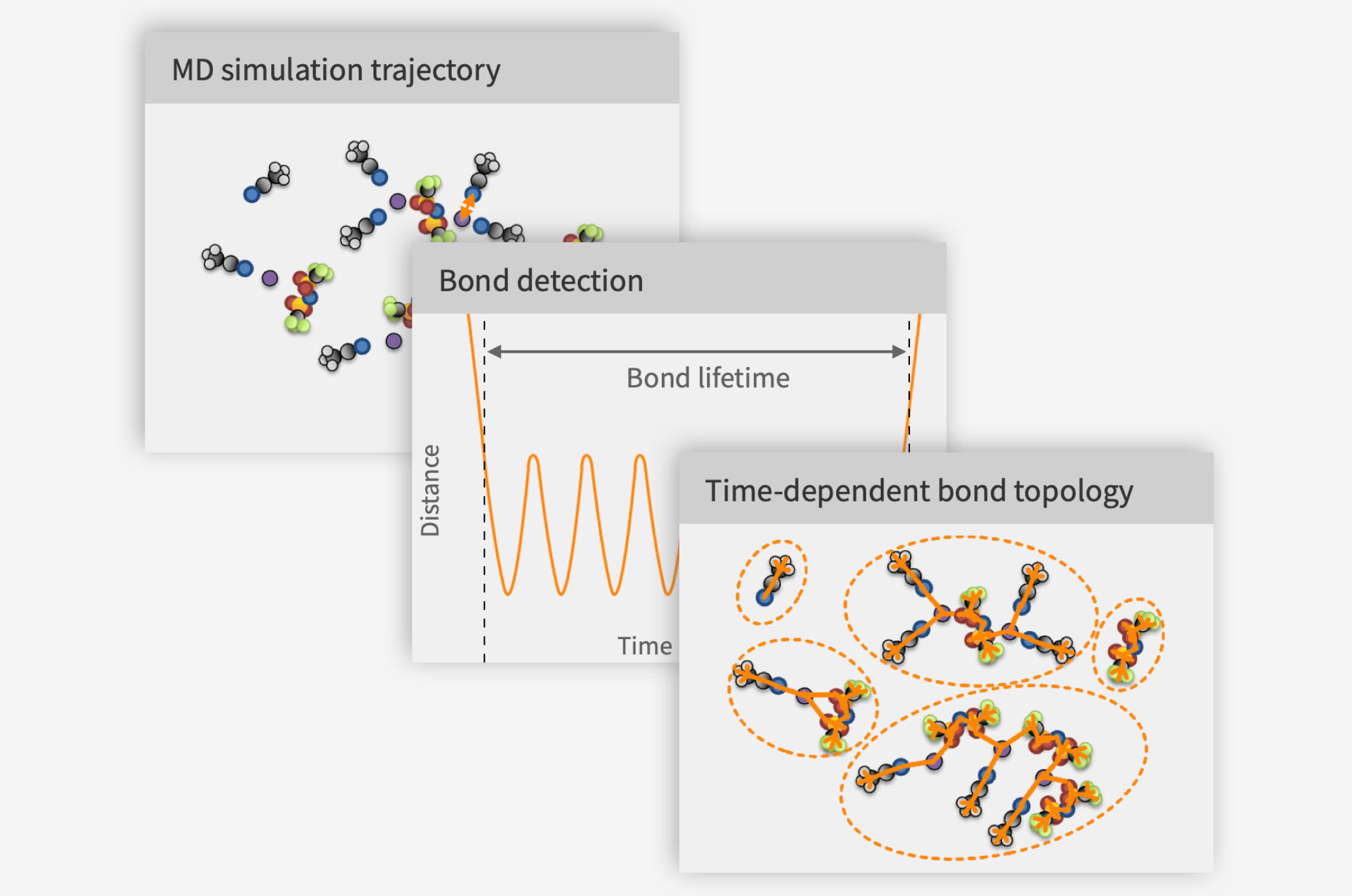

To extract useful data from these simulations, Compular’s CHAMPION, a software tool, analyzes how ions move together. It calculates what’s called Onsager coefficients, which describes how different ions affect each other’s motion (see Figure 2). From these, we derive four key transport properties:

- Ionic conductivity: how efficiently ions carry electric charge through the electrolyte

- Salt diffusivity: how fast ions spread out in the electrolyte

- Transference number: the fraction of the current carried by the cation

- Thermodynamic factor: how ion–ion interactions influence diffusion and concentration behavior

Typically, calculating these properties requires long simulations because random motion (or “noise”) from non-interacting ions makes it harder to get accurate results. But CHAMPION improves efficiency by focusing only on the meaningful interactions between nearby ions, reducing the required simulation time by about 90% to approximately 10 nanoseconds.

Figure 2: Schematic representation of the MD simulations; Key transport properties are calculated based on the motion of atoms governed by Newtonian mechanics

The Workflow: From Atomic Interactions to Battery Performance

Here’s how the combined modeling approach works:

- Molecular Dynamics Simulations: Compular’s lab tool runs MD simulations to extract crucial electrolyte properties like conductivity and diffusivity. These simulations provide insights into how electrolyte composition affects battery behavior, particularly under different temperatures and salt concentrations.

- Integrating Data into GT-AutoLion: A Python script transfers the extracted electrolyte data into the GT-AutoLion simulation framework. The data is structured into a reference object (XYZMap) that incorporates temperature/concentration-dependent electrolyte properties.

- Simulating Battery Performance: Using these electrolyte properties, GT-AutoLion predicts voltage vs. capacity curves for both energy-dense and power-dense cells. This allows for comparative analysis under varying temperatures and charging rates.

Simulation Findings: Electrolyte Properties and Their Impact on Battery Performance

When we tested these models, we found some interesting trends.

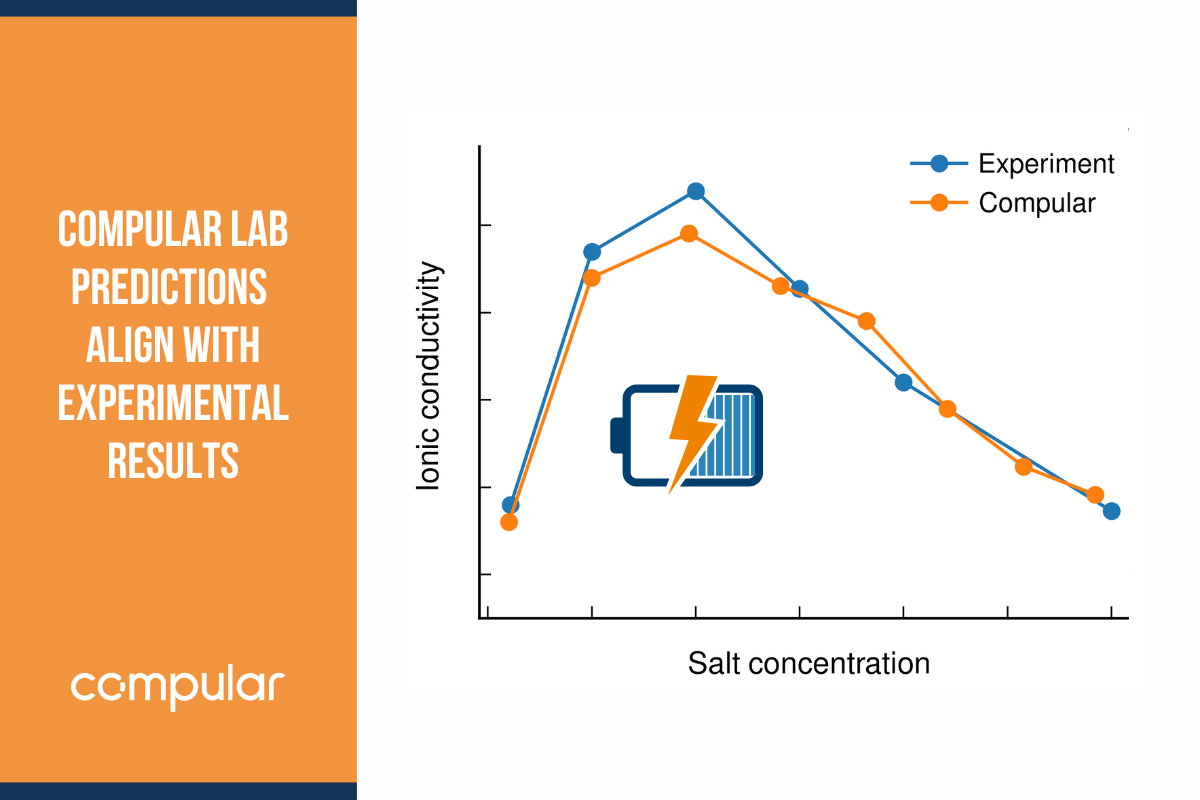

MD simulations reveal the following (Figure 3):

- Ionic conductivity and salt diffusivity decrease at lower temperatures, affecting overall battery efficiency.

- There is an optimal salt concentration (~1 M) that maximizes conductivity.

- Transport properties vary significantly with electrolyte composition and temperature, influencing battery performance.

Figure 3: Transport properties as a function of salt concentration at three temperatures, as predicted by using molecular dynamics simulations using Compular Lab

Electrochemical Battery Modeling using GT-AutoLion

By incorporating atomic-scale insights, GT-AutoLion enables:

- Accurate predictions of voltage vs. capacity for power-dense and energy-dense cells.

- Insights into how electrolyte behavior impacts capacity, especially under high C-rates and low temperatures.

- A better understanding of trade-offs between power and energy density in different applications.

Figure 4: Voltage vs. capacity for power-dense and energy-dense Li-Ion cells at different temperatures and C-rates

Conclusion: The Future of Battery Simulation

The progression of battery technology will rely heavily on the integration of multiscale simulation techniques that connect molecular-level behavior with system-level performance. With enhanced prediction accuracy and faster innovation, the future of lithium-ion is brighter than ever. If you are interested to read more about battery modeling you can read blogs on “Solving the problem of missing parameters in cell models” and “How can we model the effect of solvent breakdown on the performance of your batteries?” or contact us at .

Read more details in the whitepaper.